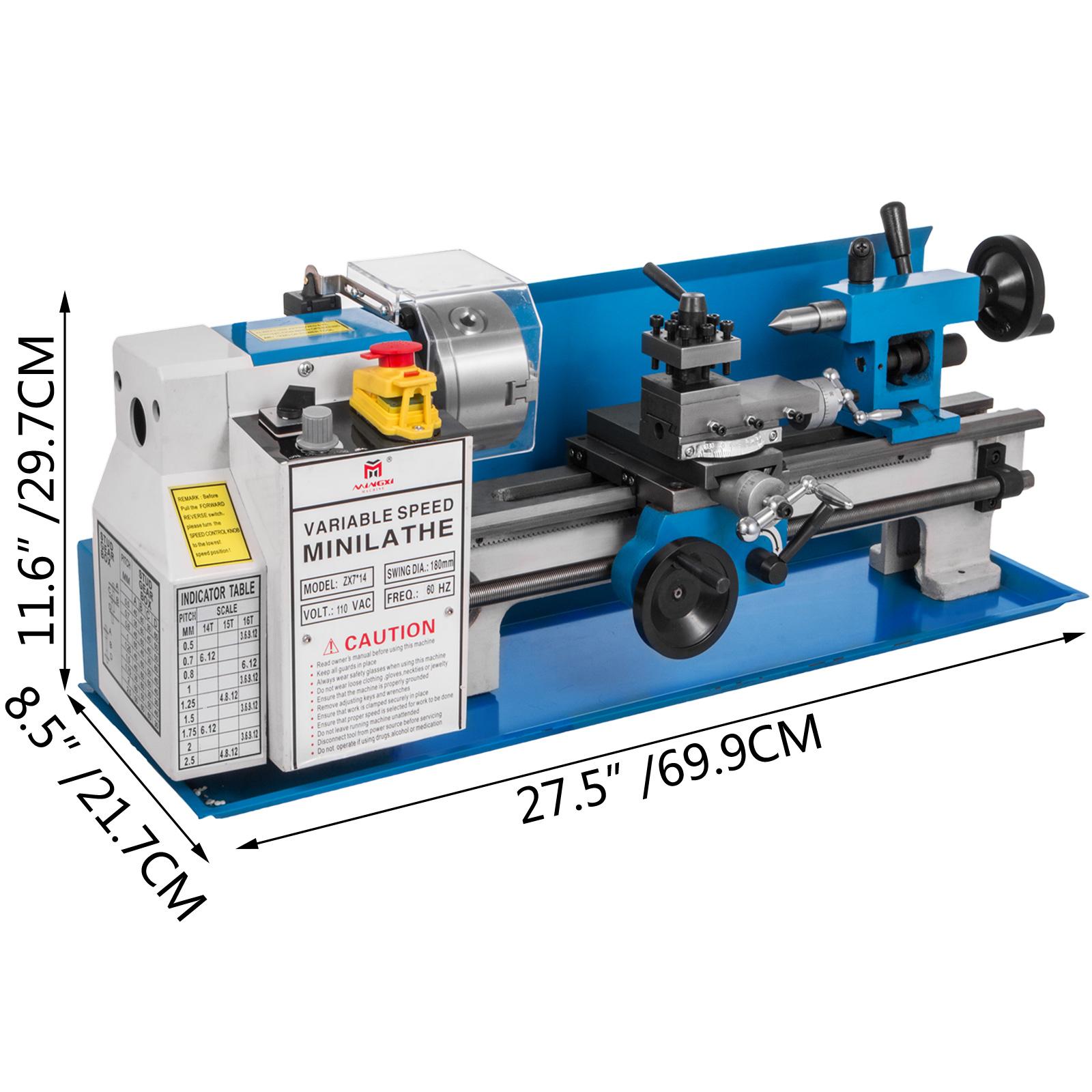

VEVOR Metal Lathe 7′′ x 14′′, Precision Bench Top Mini Metal Lathe 550W Precision Metal Lathe Variable Speed 50-2500 RPM Nylon Gear with A Movable Lamp

$73.95

-

Returns & Exchanges within 30 daysAny return for unsatisfied item(s) is available in 30 days

-

Worry-Free ReturnsSeller covers return shipping

-

Money Back GuaranteeA full refund within one week upon receiving your return

-

3-Month WarrantyCovering any possible defect in materials and workmanship

Brand Introduction

VEVOR is a leading brand that specializes in equipment and tools. Along with thousands of motivated employees, VEVOR is dedicated to providing our customers with tough equipment & tools at incredibly low prices. Today, VEVOR has occupied markets of more than 200 countries with 10 million plus global members.

Why Choose VEVOR?

1.Tough Quality Assurance

2.Incredibly Low Prices

3.Fast & Secure Delivery

4.30-Day Free Returns

5.24/7 Professional Customer Service

Product Description

7″ X 14″ Variable-speed Metal Lathe With A Movable Lamp

The 7 x 14 Inch Precision Mini Benchtop Lathe features a 3-jaw chuck, a MT3 spindle taper, a MT2 tailstock taper, a tool rest and a 3/4 HP motor, designed to perform various types of metal turning, simple to operate. Through high frequency quenching process and precision grinding of high-quality cast iron bed. 50-2500RPM spindle speed sub-level of two tranches spindle gear change speed control, continuously adjustable. A movable lamp is free for you.

Heavy & Sturdy Machine

Features a 7 inch swing over bed, 13.78 inch distance between centers and 21mm spindle bore. Includes a thread range of 12-52 TPI, threading dial indicator and standard and metric handwheel graduations.

Infinitely Variable Speeds

Variable speed from 50-2500 RPM. Forward and reverse in all speeds. Operate either manually or with the adjustable auto feed rate. The feed speed can be adjusted according to the requirements of different workpieces.

High Accuracy Chuck

3-jaw self-centering chuck has gone tested with accuracy and repeatability to set cylindrical materials steadily. Backsplash guard included. Spindle is supported by precision tapered roller bearings, spindle accuracy within 0.01mm.

Four-way Tool Post

T-slotted compound slide with four-way tool post, easy to change quickly. Bevel cutting can be made by adjusting the angle of the compound rest with the lever.

Professional Cross Slide

Designed with abrasive resistance, moving blades freely with feed rod. 16 TPI reversible lead screw. The v-slideways with distance between center: 350mm(13.78″). A lamp is for acurate operation in a dark environment.

Wide Applications

Suitable for processing jobs, like counter face turning, driling, threading and cutting jobs on materials made up of round bar. All accessories are well packed.

Specifications

Power of Motor: 550W DC Single Phase

Variable Speed: 50-2500PRM

Swing Over Bed: 180 mm (7.09″)

Chuck Diameter: 100 mm (3.94″)

Centers Distance: 350 mm (13.78″)

Spindle Bore: 21 mm (0.82″)

Inch Thread: 12-52 T.P.I

Metric Thread: 0.5-2.5 mm

Net Weight: 40 kg (88.18 lb)

Package Content

1 x Mini Metal Lathe

1 x Working Light

3 x Chuck Jaw

1 x Chuck Wrench

2 x Wrench

1 x Oil Can

5 x Hex Wrench

9 x Plastic Nylon Gear

2 x Handle

4 x Rubber Feet

4 x Screws

1 x Tool Box

- 【STURDY IRON CONSTRUCTION】- The mini metal lathe bed is made of high grade iron. Equipped with nylon gears, this lathe machine is wear-resistant, durable, more accurate rotation and professional. Mini metal lathe power of motor: 550W. The full-length splashguard provides maximum protection.

- 【INFINITELY VARIABLE SPEEDS】- Variable speed from 50-2500 RPM. Forward and reverse in all speeds. Operate either manually or with the adjustable auto feed rate. The handness and accuracy of the v-slideways are obtained by raw material, heat hardening and grinding. Emergency stop buttom included.

- 【ACCURATE 3-JAW CHUCK】- Mini metal lathe chuck, 3-jaw self-centering chuck, for setting cylindrical materials steadily. Backsplash guard included. Spindle is supported by precision tapered roller bearings, spindle accuracy within 0.01mm. A free lamp is included.

- 【PROFESSIONAL COMPOUND REST】- The mini metal lathe quick change tool post can achieve positions of internal cutting, face cutting and bevel cutting by changing the tool post angle and adjusting the compound rest. Professional cross slide is designed with abrasive resistance, moving blades freely with feed rod.

- 【WIDE APPLICATION】- Driven by DC motor, this mini metal lathe cut off tool can be used in areas such as mini precision parts processing, sample processing and modeling works.

Related products

jeans